Description

M-CHEM 300 - Acid Resistant Epoxy Novolac Coating

Is a high-build, solvent free Epoxy Novolac Coating, providing excellent resistance to a wide range of concentrated acids and industrial chemicals.

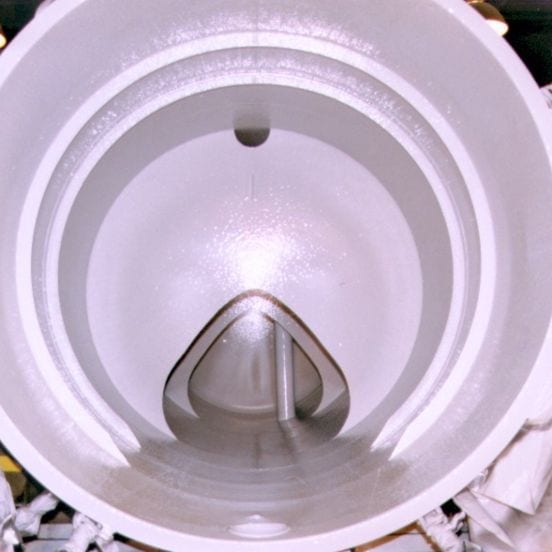

The material is suitable for a variety of applications including as a lining for bunding and secondary containment or as an internal lining for process equipment such as pressure vessels operating below 60°C.

M-CHEM 300 – Acid Resistant Epoxy Novolac Coating is proven to protect against Sulfuric Acid 98%, Hydrochloric Acid 36%, Phosphoric Acid 75% and Hydrobromic Acid 40%.

Typical Uses

- Acid Resistant lining for Process Columns

- As a Chemical Storage Tank Lining

- To protect Bunds & Containments from chemical attack

Please contact us to discuss your project before purchasing this material to confirm suitability.

Application Guide

- All oil and grease must be removed from the surface using an appropriate cleaner such as MEK or similar type solvent.

- All surfaces must be abrasive blasted to ISO 8501/4 Standard SA2.5 (SSPC SP10/ NACE 2) minimum blast profile of 75 microns using an angular.

- Once blast cleaned the surface must be degreased and cleaned using MEK or similar type solvent.

- All surfaces must be coated before gingering or oxidation.

Existing Concrete

- If the concrete surface is contaminated, pressure wash using clean water.

- Once the concrete is dry, lightly abrasive blast or scarify taking care not to expose the aggregate.

- Clean all dust and debris from the surface and take several moisture readings and prime with M-PRIME 100 – Low Viscosity Epoxy Concrete Primer or M-PRIME 104 – Damp Tolerant Concrete Primer dependant on moisture readings obtained.

- Apply M-PRIME 100 or M-PRIME 104 at a target wet film of 150 microns, allow to cure before overcoating.

- For very porous surfaces a second coat of primer may be required.

New Concrete

- Allow new concrete to cure for a minimum of 21 days. Lightly abrasive blast or scarify to remove any surface laitance.

- Clean all dust and debris from the surface and take several moisture readings and prime with M-PRIME 100 – Low Viscosity Epoxy Concrete Primer or M-PRIME 104 – Damp Tolerant Concrete Primer dependant on moisture readings obtained.

- Apply M-PRIME 100 or M-PRIME 104 at a target wet film of 150 microns, allow to cure before overcoating.

- For very porous surfaces a second coat of primer may be required.

Prior to mixing please ensure the following:

- The base component is at a temperature between 15-25°C.

- Do not apply the material when the ambient or substrate temperature is below 10°C or less than 3°C above dew point.

- Transfer the contents of the Activator unit into the Base container.

- Using a low speed electric paddle mixer, mix the 2 components until a uniform material free of any streaks is achieved.

- Once mixing is complete, use the mixed paste as soon possible.

Use all mixed material within 20-25 minutes at 20°C.

Brush & Roller

- Pour the mixed material into a paint kettle or paint tray (this will maximise the usable life).

- Stripe coat all edges, joints & corners.

- Once the stripe coat has cured and is capable of being overcoated, apply a basecoat at a target wet film thickness of 400-500 microns.

- Once the basecoat has cured sufficiently, (approximately 4 hours at 20°C) apply a topcoat at a target wet film thickness of 400-500 microns.

Airless Spray

Spray application should be carried out by airless spray using a 45:1 ratio pump with an attached hot water pump to heat the spray lines.

- The temperature around the spray lines should be kept around 25-35°C.

- Spray pressure of 3600psi and a tip size of 19-23 thou should be used.

- Use as short a line as possible to maintain product temperature (maximum 8 meters).

- Circulate the product for a short time to achieve temperature equilibrium.

- Stripe coat all edges, joints & corners.

- Once the stripe coat has cured and is capable of being overcoated, apply a basecoat at a target wet film thickness of 400-500 microns.

- Once the basecoat has cured sufficiently, (approximately 4 hours at 20°C) apply a topcoat at a target wet film thickness of 400-500 microns.

To enhance the properties of this material, post curing will be required.

- Allow the product to cure for at least 4 hours at 20°C.

- Raise the coating and substrate temperature progressively to 60 – 100°C for up to 8 hours.

Post curing will result in improved mechanical, thermal and chemical resistance properties.

| Appearance | Base Activator Mixed | Highly structured thixotropic liquid Amber liquid Thixotropic liquid |

| Mixing Ratio | By Weight By Volume | 4:1 3:1 |

| Density | Base Activator Mixed | 1.41 1.02 1.32 |

| Solids Content | 100% | |

| Sag Resistance | Nil at | 500 microns |

| Usable Life | 10°C 20°C 30°C | 50 minutes 25 minutes 12 minutes |

| Theoretical Coverage | Basecoat – minimum wet film thickness of 400 microns Topcoat – minimum 400 film thickness of 400 microns | 2.5 sqm /ltr 2.5 sqm/ltr |

| Cure Times at 20°C | Minimum overcoating time Maximum overcoating time Water/ sea water immersion Chemical immersion | 4 Hours 12 hours 4 days 7 days |

| Storage Life | Unopened and stored in dry conditions (15-30°C) | 5 years |

| Abrasion Resistance | Test to Taber CS17 Wheels/1 Kg load | 138mg loss/1000 cycles 0.18cc loss/1000 cycles |

| Adhesion | Tensile Shear to ASTM D1002 on abrasive blasted mild steel with 75 micron profile | 208 kg/ cm² (2950 psi) |

| Compressive Strength | Tested to ASTM D 695 | 984kg/cm² 13,950psi |

| Corrosion Resistance | Tested to ASTM B117 | 5000 hours |

| Flexural Strength | Tested to ASTM D790 | 871kg/cm² 12,300ps |

| Hardness | Shore D to ASTM D2240 | 85 |

| Heat Distortion | Tested to ASTM D648 at 264psi fibre stress | 20°C Cure 52°C 100°C Cure 75°C |

| Heat Resistance | Suitable for use in immersed conditions at temperatures up to: Suitable for use in dry conditions at temperatures up to dependant on load: | 60°C 200°C |

| Acetic Acid 10% at 30˚C Ammonia Hydroxide 30% at 45˚C Benzene 100% at 35˚C Butanol 100% at 40˚C Chromic Acid 10% at 40˚C | De-ionised Water at 40˚C Ethanol 100% at 45˚C Hydrobromic Acid 40% at 30˚C Hydrochloric Acid 36% at 35˚C Nitric Acid 10% at 30˚C | Phosphoric Acid 75% at 45˚C Steam out at 180˚C Sulphuric Acid 98% at 40˚C Toluene 100% at 40˚C Xylene 100% at 40˚C |

Please contact us to discuss your project before purchasing this material to confirm suitability.