Rotary valves are commonly used in various industries to control the flow of bulk materials, such as powders, granules, and liquids. Over time, the continuous operation of rotary valves can lead to wear and abrasion, which can negatively affect their performance and lifespan. To protect rotary valves from wear, several strategies can be employed. Here are some common methods for rotary valve wear protection:

Hard-facing: The surfaces of the rotary valve that come into contact with the material being transported can be hard-faced. Hard-facing involves applying a wear-resistant material, such as tungsten carbide or chromium carbide, to the valve’s contact surfaces. This helps to minimize wear and extend the valve’s life.

Ceramic coatings: Ceramic coatings are another effective method for protecting rotary valves from wear. These coatings provide a high level of hardness and abrasion resistance, reducing the impact of abrasive materials on the valve surfaces.

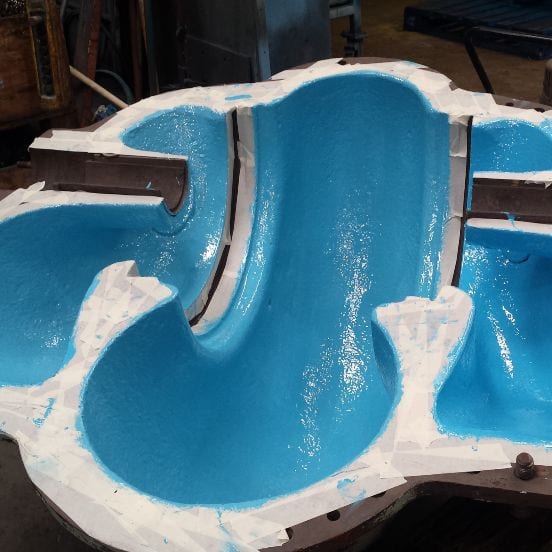

Polymeric liners: Installing polymeric liners on the internal surfaces of the rotary valve can help prevent wear. Liners made from materials such as polyurethane or nylon are commonly used for this purpose. They provide a protective barrier between the valve’s metal surfaces and the abrasive materials, reducing wear and friction.

Anti-wear coatings: Applying anti-wear coatings on the valve surfaces can also enhance wear protection. These coatings typically consist of specialized compounds designed to reduce friction and resist abrasion. Examples include Teflon (polytetrafluoroethylene) coatings or other fluoropolymer-based coatings.

Regular maintenance and inspection: Implementing a comprehensive maintenance and inspection program is crucial for detecting wear and addressing any issues promptly. This can include routine lubrication, cleaning, and visual inspections to identify signs of wear or damage. Regular maintenance helps to optimize the performance and longevity of the rotary valve.

Material selection: Choosing the appropriate materials for the rotary valve construction is essential. Consideration should be given to the type of material being handled, its abrasive properties, and the operating conditions. Opting for materials with higher hardness or corrosion resistance can help mitigate wear.

Proper alignment and installation: Correct alignment and installation of the rotary valve are essential to minimize wear. Misalignment can cause uneven loading and increased friction, leading to accelerated wear. Following the manufacturer’s guidelines and recommendations for installation and alignment is crucial.

It’s worth noting that the specific wear protection measures employed for rotary valves can vary depending on the application and industry. Consulting with experts or valve manufacturers who specialize in wear protection can provide valuable insights and tailored solutions for rotary valve wear prevention.

-

M-CERAMIC 100 – Epoxy Ceramic Putty

£97.30 – £247.00 Excl VAT Select options -

M-CERAMIC 200 – Epoxy Ceramic Coating

£97.30 – £247.00 Excl VAT Select options -

M-CERAMIC 401 – Epoxy Ceramic Wear Compound – High Abrasion

£317.70 Excl VAT Add to basket