Description

M-CHEM 200 – Chemical Resistant Polyurethane Coating

M- CHEM 200 – Chemical Resistant Polyurethane Coating is designed principally for the long-term protection of tanks, bunds, pipelines and other concrete or steel structures in contact with diluted acidic solutions and industrial chemicals.

It is a high build coating, formulated using the latest solvent free polyurethane coating technology.

When cured the material exhibits a high degree of flexibility allowing for substrate movement without cracking.

Typical Uses

- Bund lining & coating

- Storage tank lining

- Structural steel

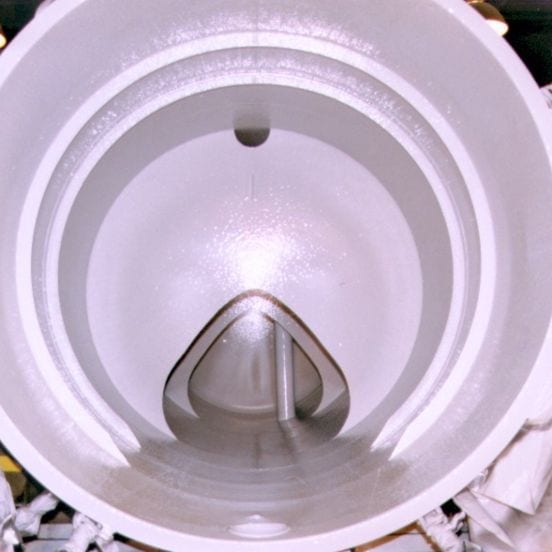

- Internal pipe lining

- Chemical process flooring

- Internal process vessel surfaces

Please contact us to discuss your project before purchasing this material to confirm suitability.

Application Guide

- All oil and grease must be removed from the surface of the repair using an appropriate cleaner such as MEK or similar solvent. For optimum performance, the surface should be grit-blasted to ISO 8501/4 Standard SA2.5 (SSPC SP10/ NACE 2) and a minimum blast profile of 75 microns using an angular abrasive.

- Once blast cleaned, the surface must be degreased and cleaned using MEK or similar solvent. All surfaces must be repaired before gingering or oxidation occurs.

- Where abrasive blast cleaning is not possible (excluding salt contaminated surfaces) the surface should be roughened by, needle gun or grinding. Under these conditions’ adhesion levels will not be optimal although still satisfactory for most applications.

For salt contaminated surfaces the area must be grit-blast cleaned as mentioned above and left for 24 hours to allow any ingrained salts to come to the surface.

- After this 24-hour period the surface must be washed with MEK prior to brush blasting to remove the surface salts. This process must be repeated until all ingrained contaminants have been sweated out of the surface.

Remove any contamination and lightly abrasive blast or scarify taking care not to expose the aggregate before application of M-CHEM 200PU. Allow new concrete to cure for a minimum of 21 days and likewise treat to remove any surface laitance before coating.

For optimum results on damp concrete, condition with MPR 101CS – Damp Tolerant Concrete Primer Where the concrete is dry but highly porous, it is recommended to prime the concrete with MPR 100CS – Concrete Primer

Prior to mixing please ensure the following:

- The base component is at a temperature between 15-25°C.

- Do not apply the material when the ambient or substrate temperature is below 10°C and not less than 3°C above the dew point.

- Transfer the contents of the Activator unit into the Base container.

- Using a low speed electric paddle mixer, mix the 2 components until a uniform material free of any streaks is achieved.

- Once mixing is complete, use the mixed coating as soon possible after mixing.

Use all mixed material within 15 minutes at 20°C.

Application – Brush & Roller

- Pour the mixed material into a paint kettle or paint tray (this will maximise the usable life)

- Using a 50mm synthetic brush, stripe coat all edges, joints & corners.

- Once the stripe coat has cured sufficiently and is capable of being overcoated, apply the basecoat to all surfaces at minimum 350-400 microns.

- Once the basecoat of material has cured sufficiently, approximately 6-8 hours at 20°C, apply the intermediate coat to all surfaces at a minimum 400 microns.

- Once the intermediate coat has cured sufficiently, approximately 6-8 hours at 20°C, apply the topcoat to all surfaces at a minimum 350-400 microns.

- Minimum finished coating thickness needs to be in excess of 700 microns.

| Appearance | Base Activator Mixed | Highly structured thixotropic liquid Amber liquid Thixotropic liquid |

| Mixing Ratio | By Weight By Volume | 3.25:1 3:1 |

| Density | Base Activator Mixed | 1.31 1.22 1.29 |

| Solids Content | 100% | |

| Sag Resisitance | Nil at | 400 microns |

| Usable Life | 10°C 20°C 30°C | 40 minutes 20 minutes 10 minutes |

| Coverage | 350 microns M-CHEM 200 theoretical coverage rate (Must be applied as a 2 coat system to properly prepared surfaces) | 2.85m² per ltr per coat |

| Cure Times | Minimum overcoating time @ 20°C 6 hours 30°C Maximum overcoating time 20°C Water/ sea water immersion @ 20°C Chemical immersion @20°C | 6 hours 24 hours 3 days 5 days |

| Storage Life | Unopened and stored in dry conditions (15-30°C) | 2 years |

| Adhesion | Tensile Shear to ASTM D1002 on abrasive blasted mild steel with 75 micron profile | 169kg/cm² 2400psi |

| Impact Resistance | Tested to ASTM G14 | 8.6 joules |

| Compressive Strength | Tested to ASTM D 695 | 552kg/cm² (7830psi) |

| Corrosion Resistance | Tested to ASTM B117 | 5000 hours |

| Flexural Strength | Tested to ASTM D790 | 755kg/cm² (10700psi) |

| Hardness | Shore D to ASTM D2240 | 80 |

| Heat Resistance | Suitable for use in immersed conditions at temperatures up to: Suitable for use in dry conditions at temperatures up to dependant on load: | 70°C 120°C |

| Chemicals & Concentrations | Test Temperature |

| Chlorine (Wet) Chloramine Chlorine Dioxide (Wet) Sodium Hypochlorite 15% | 30˚C 30˚C 35˚C 30˚C |