Description

M-CHEM 400 - Chemical Resistant High Temperature Coating

Is an Extend Cure Version of M-CHEM 400 the material is a solvent free coating utilising the latest novolac polymer technology. The material provides excellent chemical protection for applications subject to high service temperatures.

The products designed for the long-term protection of steel and concrete surfaces subject to constant chemical immersion at elevated temperatures.

Once cured the material is capable of withstanding service temperatures up to 90°C continuous immersion, dependent on chemical contact.

M-CHEM 400 is proven to protect against 98% Sulphuric Acid at 75°C, 36% Hydrochloric Acid at 50°C and 40% Phosphoric Acid at 60°C

Typical Uses

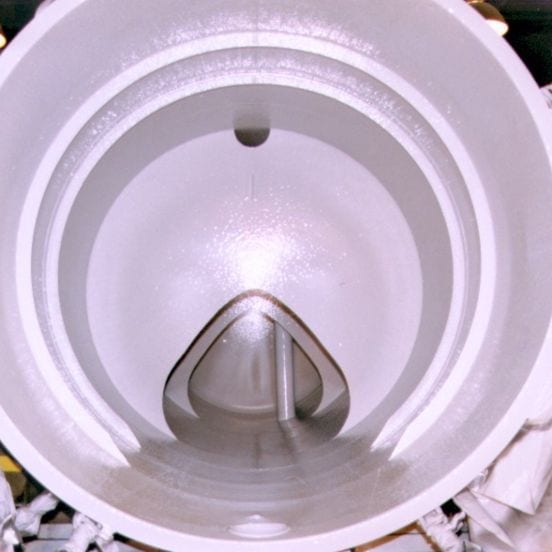

- Tank lining & process vessels

- Lining for Chemical drains and channels

- Lining for Internal Pipe Surfaces

- Protection for Chemical Sumps

- Lining for Pressure Vessels

Please contact us to discuss your project before purchasing this material to confirm suitability.

Application Guide

- All oil and grease must be removed from the surface using an appropriate cleaner such as MEK or similar type solvent.

- All surfaces must be abrasive blasted to ISO 8501/4 Standard SA2.5 (SSPC SP10/ NACE 2) minimum blast profile of 75 microns using an angular.

- Once blast cleaned the surface must be degreased and cleaned using MEK or similar type solvent.

- All surfaces must be coated before gingering or oxidation.

PLEASE NOTE: Soluble salt contaminated surfaces the substrate must be pressure washed with clean water and checked for salt contamination this process may need to be repeated several times.,

Existing Concrete

- If the concrete surface is contaminated, pressure wash using clean water.

- Once the concrete is dry, lightly abrasive blast or scarify taking care not to expose the aggregate.

- Clean all dust and debris from the surface and prime with M-PRIME 100 – Low Viscosity Epoxy Concrete Primer or M-PRIME 104 – Damp Tolerant Concrete Primer

- Apply either primer at target WFT of 150 microns, leave to cure for 3 hours (20°C) before overcoating.

New Concrete

- Allow new concrete to cure for a minimum of 21 days and treat to remove any surface laitance.

- Check the moisture content of the concrete prior to coating (8% moisture content or below).

- Lightly scarify the surface taking care not to expose the aggregate.

- Clean all dust and debris from the surface and prime with Maxprime 100 low viscosity epoxy primer.

- Apply either primer at 150 microns WFT, leave to cure for 3 hours 20°C before overcoating.

Prior to mixing please ensure the following:

- The base component is at a temperature between 15-25°C.

- Do not apply the material when the ambient or substrate temperature is below 10°C or less than 3°C above dew point.

- Transfer the contents of the Activator unit into the Base container.

- Using a low speed electric paddle mixer, mix the 2 components until a uniform material free of any streaks is achieved.

- Once mixing is complete, use the mixed paste as soon possible.

Use all mixed material within 20-25 minutes at 20°C.

Brush or Roller Applications

- Pour the mixed material into a paint kettle or paint tray (this will maximise the usable life).

- Using a 50mm wide synthetic brush, stripe coat all edges, joints, corners and equipment with the mixed material. The stripe coat must be approximately 100mm wide, at 500 microns wet film thickness.

- Once the stripe coat has cured sufficiently and is capable of being overcoated, apply the 1st coat of mixed product to all surfaces at 500 microns wet film thickness.

- Once the 1st coat of material has cured sufficiently, approximately 8 hours at 20°C, apply a 2nd coat of material to all surfaces at 500 microns wet film thickness.

Spray set up & Application

- Spray application should be carried out by heated plural feed spray rig.

- The temperature of the base component should be kept around 35°C.

- Spray pressure of 3600psi and a tip size of 19-23 thou should be used.

- Using a 50mm wide synthetic brush, stripe coat all edges, joints, corners and equipment with the mixed material. The stripe coat must be approximately 100mm wide, at 400 microns wet film thickness.

- Once the stripe coat has cured sufficiently and is capable of being overcoated, apply MAXCHEM 400 to all surfaces at 1000 microns wet film thickness.

To enhance the properties of this material, post curing will be required.

- Allow the product to cure for at least 4 hours at 20°C.

- Raise the coating and substrate temperature progressively to 60 – 80°C for up to 8 hours.

Post curing will result in improved mechanical, thermal and chemical resistance properties.

| Appearance | Base Activator Mixed | Grey/ red paste Amber fluid Grey/ red Liquid |

| Mixing Ratio | By Weight By Volume | 5.34:1 4:1 |

| Density | Base Activator Mixed | 1.40 1.05 1.34 |

| Solids Content | 100% | |

| Sag Resisitance | Nil at | 1000 microns |

| Usable Life | 10°C 20°C 30°C | 30 minutes 15 minutes 7 minutes |

| Theoretical Coverage | The material should be applied in a single coat at 1000 microns wet film thickness | 1 sqm /ltr |

| Cure Times | Minimum overcoating time at 20°C Maximum overcoating time at 20°C Water/ sea water immersion at 20°C Chemical immersion at 20°C | 4 hours 12 hours 96 hours 7 days |

| Storage Life | Unopened and stored in dry conditions (15-30°C) | 5 years |

| Adhesion | Tensile Shear to ASTM D1002 on abrasive blasted mild steel with 75 micron profile | 188kg/cm² 2650psi |

| Compressive Strength | Tested to ASTM D 695 | 592kg/cm² 8,400psi |

| Corrosion Resistance | Tested to ASTM B117 | 5000 hours |

| Flexural Strength | Tested to ASTM D790 | 480kg/cm² 6800psi |

| Hardness | Shore D to ASTM D2240 | 20°C 86 100°C 84 150°C 72 |

| Heat Distortion | Tested to ASTM D648 at 264psi fibre stress | 20°C Cure 62°C 100°C Cure 98°C 150°C Cure 112°C |

| Heat Resistance | Suitable for use in immersed conditions at temperatures up to: Suitable for use in dry conditions at temperatures up to dependant on load: | 110°C 170°C |

| Enhanced Chemical Resistance when post cured Acetic Acid 10% at 50˚C Ethanol 100% at 75˚C Sulphuric Acid 98% at 75˚C Sulphuric Acid 25 -75% at 90˚C Hydrochloric Acid 10-36% at 50˚C Phosphoric Acid 20-40% at 60˚C Nitric Acid 5% at 50˚C Sodium Hydroxide 40% at 90˚C Sodium Chloride 20% at 90˚C | Chemical Resistance tested at 20˚C Chromic 10% Hydrobromic 40% Hydrochloric 36% Nitric 10% Nitrous 10% Phosphoric 75% Sulphuric 98% Acetic 10% Carbonic 30% Citric 30% Folic 20% Formic 10% Lactic 10% Ammonium hydroxide 30% Potassium hydroxide 20% Sodium hydroxide 40% Sodium Bisulfate 40% | Chemical Resistance tested at 20˚C Butanol 100% Ethylene glycol 100% Hexanol 100% Propylene glycol 100% Aniline 100% Diethanolamine 100% Hydrazine 100% Methylamine 40% Cyclohexane 100% Hexane 100% Octane 100% Benzene 100% Naphtha 100% Toluene 100% Xylene 100% |

Please contact us to discuss your project before purchasing this material to confirm suitability.