Description

M-CERAMIC 401 – Epoxy Ceramic Wear Compound – High Abrasion & Impact

Is a Solvent free Epoxy Ceramic Wear Compound containing graded Silicone Carbide beads (2.0-3.0mm in diametre).

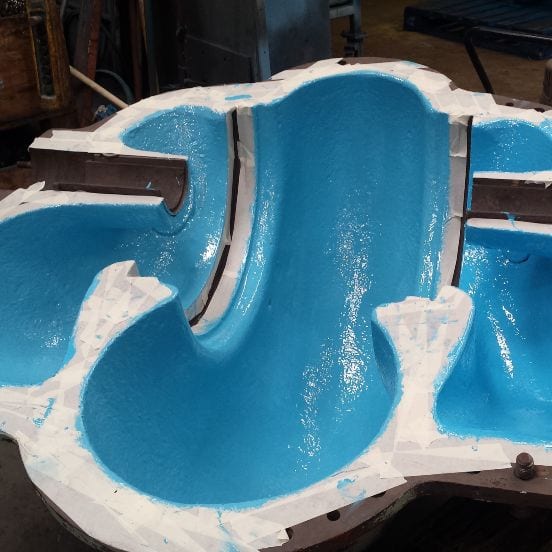

The product when cured is particularly suited for larger particles such as aggregates and wet slurries, typically found in dredging, quarrying and steel industries.

The product can be applied up to 10mm in a single application without shrinking. Normal application method is by plastic applicator tool, trowel and spatula.

Typical Uses

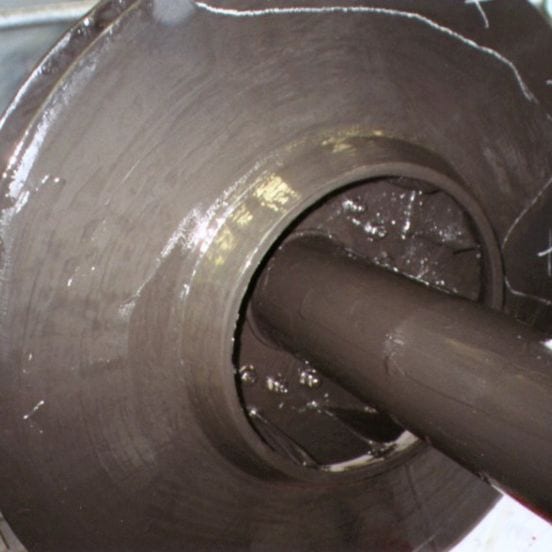

- Lining for Dreding Pumps

- Wear Resistant lining for Bins & Hoppers

- To Protect Fan Blades & Fan Housings

- Create Wear Plates

- Protect Pipe Elbows

- As a filler for lost Ceramic Wear Tiles

Application Guide

- All oil and grease must be removed from the surface using an appropriate cleaner such MEK or similar type solvent.

- All surfaces must be abrasive blasted to ISO 8501/4 Standard SA2.5 (SSPC SP10/ NACE 2) minimum blast profile of 75 microns using an angular.

- Once blast cleaned, the surface must be degreased and cleaned using MEK or similar type solvent.

- All surfaces must be coated before gingering or oxidation.

- All oil and grease must be removed from the surface using an appropriate cleaner such as MEK.

- All surfaces must be mechanically abraded using handheld grinders to ISO 8501/4 ST3 (SSPC SP3 ST3).

- Once abraded, the surface must be degreased and cleaned using MEK or similar type material.

- All surfaces must be repaired before gingering or oxidation occurs.

Prior to mixing please ensure the following:

- The base component is at a temperature between 15-25°C.

- Do not apply the material when the ambient or substrate temperature is below 10°C or less than 3°C above dew point.

Mixing full units or by part-mixing.

- If mixing the whole unit please ensure as much of the base and activator is dispensed from the plastic container onto a clean plastic mixing surface.

- Mix using the spatula provided until a uniform material free of any streakiness is achieved while ensuring no unmixed material is left on the spatula or the mixing surface.

- For part mixing, using a spatula place 2 equal measures from the base unit onto a clean plastic mixing surface.

- Clean the spatula thoroughly and then take 1 equal measure from the Activator unit and place alongside the base measures. Mix as above.

Use all mixed material within 25 minutes at 20°C.

- The mixed material should be applied directly to the prepared metal surface at a minimum thickness of 6mm using a spatula or applicator tool.

| Appearance | Base Activator Mixed | Dark grey paste Light grey paste Mid grey paste |

| Mixing Ratio | By Weight By Volume | 2:1 2:1 |

| Density | Base Activator Mixed | 2.28 2.26 2.27 |

| Volume Capacity | 2200cc/5kg | |

| Solids Content | 100% | |

| Sag Resistance | Nil at | 10mm |

| Usable Life | 10°C 20°C 30°C | 60 minutes 30 minutes 15 minutes |

| Coverage | 5kg at a nominal thickness of | 0.73m² at 3mm 0.37m² at 6mm |

| Cure Times @ 20°C | Minimum overcoating time Maximum overcoating time Full Cure | 4 hours 8 hours 4 days |

| Storage Life | Unopened and stored in dry conditions (15-30°C) | 5 years |

| Abrasion Resistance | Taber H10 Wheels/1 Kg load | 42mm³ loss/1000 cycles |

| Adhesion Pull-Off | Test to ASTM D4541 on abrasive blasted mild steel with 75 micron profile | 272kg/ cm² (3840psi) |

| Adhesion Tensile Shear | Tested to ASTM D1002 on abrasive blasted mild steel with 75 micron profile | 272kg/ cm² (3840psi) |

| Compressive Strength | Tested to ASTM D 695 | 1046kg/cm² (14880psi) |

| Corrosion Resistance | Tested to ASTM B117 | 1000 hours |

| Flexural Strength | Tested to ASTM D790 | 475kg/cm² (6710psi) |

| Impact Resistance | Tested to ASTM D256 | 22J/m |

| Hardness | Shore D to ASTM D2240 | 89 |

| Heat Resistance | Full immersion resistance water/ hydrocarbon immersion to 50°C Dry heat resistance Tested to ASTM D2485 | Pass (no blisters) Pass 150°C |

| Chemical Resistance | The product resists attack by a wide variety of inorganic acids, alkalis, salts and organic media. |