Description

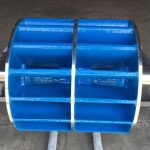

M-CERAMIC 600 – Epoxy Ceramic Underwater Coating

Is a flexible high build solvent-free epoxy coating designed for application to wet or underwater surfaces.

The ceramic enhanced product provides long term protection for steel and concrete structures against corrosion, abrasion and chemical attack.

The product cures at 5°C and is applied in a single coat at 750 microns to 1mm thickness.

Typical Uses

- Subsea Structures

- Buried and Submerged Pipelines

- Protect Risers Legs

- Oil Rig Splash Zones

- Corrosion Barrier for Piers and Jetties

Application Guide

- The surface to be coated must be free of any marine life such algae or barnacles, any degraded coating or surface corrosion must be cleaned from the surface.

- For the best results the underwater repair surface can be hydro-blasted at a minimum pressure of 3000psi. This method of preparation will ensure the majority of surface contaminants will be cleaned from the surface.

- If it is not possible to hydro-blast the surface then handheld scrapers and chisels can be used to clean the surface. If possible a rough pad should be used to try and take away any loose coating or surface corrosion.

- Please be aware that this type of surface preparation will reduce the performance of the coating.

Prior to mixing please ensure the following:

- The base component is at a temperature between 15-25°C.

- Do not apply the material when the ambient or substrate temperature is below 5°C.

- Transfer the contents of the Activator unit into the Base container.

- Using the spatula provided, mix the 2 components until a uniform material free of any streaks is achieved.

Use all mixed material within 45 minutes at 20°C.

- The material has been designed to be applied to underwater surfaces in a single coat at 750 microns to 1mm wet film thickness.

- Using the applicator tool provided the material should be pressed onto the surface.

- Ensure you do not over work the coating once applied onto the underwater surface, as a general rule if the coating has covered the repair area then leave it to cure.

- You can dress or smooth off the coating after a minimum of 4 hours after application using a gloved hand.

| Appearance | Base Activator Mixed | Grey liquid Amber liquid Grey liquid |

| Mixing Ratio | By Weight By Volume | 6.75:1 4:1 |

| Density | Base Activator Mixed | 1.67 0.99 1.54 |

| Volume Capacity | 649cc/1kg | |

| Solids Content | 100% | |

| Sag Resistance | Nil at | 1000 microns |

| Usable Life | 10°C 20°C 30°C | 90 minutes 45 minutes 22.5 minutes |

| Coverage | 1kg at a nominal thickness of | 1.333m² at 750 microns 1m² at 1000 microns |

| Cure Times @ 20°C | Minimum overcoating time Maximum overcoating time Full Cure | 6 hours 12 hours 3 days |

| Storage Life | Unopened and stored in dry conditions (15-30°C) | 5 years |

| Abrasion Resistance | Taber H10 Wheels/1 Kg load | 38mm³ loss/1000 cycles |

| Adhesion Tensile Shear | Tested to ASTM D1002 on blasted mild steel with 75 micron profile Tested to ASTM D1002 on blasted mild steel with 75 micron profile (wet) | 184kg/ cm² (2610psi) 176kg/ cm² (2500psi) |

| Corrosion Resistance | Tested to ASTM B117 | 5000 hours |

| Flexural Strength | Tested to ASTM D790 | 614kg/cm² (8710psi) |

| Impact Resistance | Tested to ASTM D256 | 32J/m |

| Hardness | Shore D to ASTM D2240 | 20°C 80 |