Description

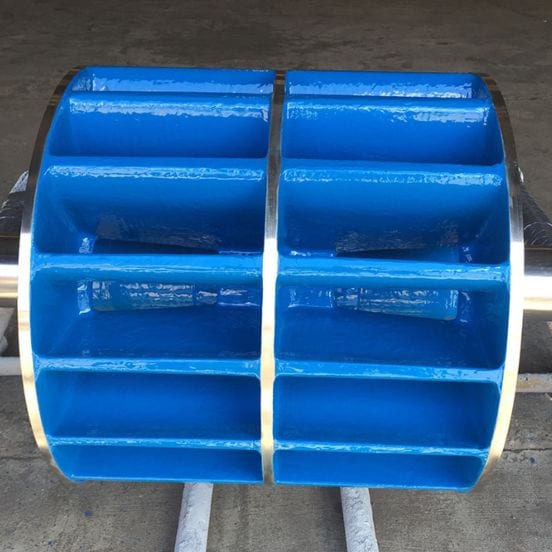

M-CERAMIC 300 - Epoxy Ceramic Efficiency Coating

Is a high performance Epoxy Ceramic Efficiency Coating with excellent erosion characteristics.

The coating is formulated using the latest solvent free, epoxy resin systems, enhanced further with the addition of high-quality graded silicone carbide fillers.

M-CERAMIC 300 – when cured has an ultra-high gloss surface finish, this helps to reduce internal friction in pumps, improve pumping efficiencies, and help to lower energy consumption.

M-CERAMIC 300 – Epoxy Ceramic Efficiency Coating is designed for the long-term protection of Pumping Systems and other Fluid Flow Equipment.

The product is supplied as a 2-component product (PART – A & PART- B), that requires mixing before use, once mixed the product can be applied directly to prepared metal surfaces by brush, squeegee or plastic applicator.

Typical Uses

- Improve Efficiency in Fluid Flow Equipment

Application Guide

- All oil and grease must be removed from the surface using an appropriate cleaner such as MEK or similar type solvent.

- All surfaces must be abrasive blasted to ISO 8501/4 Standard SA2.5 (SSPC SP10/ NACE 2) minimum blast profile of 75 microns using an angular.

- Once blast cleaned, the surface must be degreased and cleaned using MEK or similar type solvent.

- All surfaces must be coated before gingering or oxidation.

- All oil and grease must be removed from the surface using an appropriate cleaner such as MEK.

- All surfaces must be mechanically abraded using handheld grinders to ISO 8501/4 ST3 (SSPC SP3 ST3).

- Once abraded, the surface must be degreased and cleaned using MEK or similar type material.

- All surfaces must be repaired before gingering or oxidation occurs.

Prior to mixing please ensure the following:

- The base component is at a temperature between 15-25°C.

- Do not apply the material when the ambient or substrate temperature is below 5°C or less than 3°C above dew point.

- Mix both Part-A and Part-B together in full units as supplied. For small quantities us a mixing ratio of 3:1 by volume or 5:1 by weight.

- When mixing both materials, it is particularly important to have a uniform grey paste that is streak free.

- Once mixing is complete, use the mixed paste as soon possible after mixing.

Use all mixed material within 20 minutes at 20°C.

- Apply the mixed material directly to the prepared surface as soon as possible after mixing. For best results the material has been designed to be applied as a two-coat system.

- Basecoat should be applied directly to prepared and cleaned metal surface at a minimum wet film thickness of 250 microns. (light grey fluid) using a short-bristled brush, spatula, squeegee or plastic applicator.

- Topcoat should be applied directly over the basecoat as soon as the basecoat is touch but not exceeding 6 hours. Apply at a minimum wet film thickness of 250 microns (blue fluid) using a short-bristled brush, spatula, squeegee or plastic applicator.

| Appearance | Base Activator Mixed | Blue or light grey paste Amber liquid Thixotropic blue or light grey liquid |

| Mixing Ratio | By Weight By Volume | 5:1 3:1 |

| Density | Base Activator Mixed | 1.67 1.05 1.52 |

| Volume Capacity | 657cc/kg | |

| Solids Content | 100% | |

| Sag Resistance | Nil at | 400 microns |

| Usable Life | 10°C 20°C 30°C | 40 minutes 20 minutes 10 minutes |

| Coverage | 1kg unit of mixed product at a nominal thickness of | 200 microns 3.235m² 250 microns 2.628m² 300 microns 2.188m² |

| Cure Times @ 20°C | Minimum-overcoating time Maximum- overcoating time Full Cure | 2 hours 6 hours 2 days |

| Storage Life | Unopened and stored in dry conditions (15-30°C) | 5 years |

| Abrasion Resistance | Taber CS17 Wheels/1 Kg load | 24mm³ loss/1000 cycles |

| Adhesion | Tensile Shear to ASTM D1002 on abrasive blasted mild steel with 75-micron profile | 187kg/ cm² (2650psi) |

| Adhesion | Pull off Adhesion to ASTM D4541 on abrasive blasted mild steel with 75-micron profile | 202kg/ cm² (2880 psi) |

| Compressive Strength | Tested to ASTM D 695 | 735kg/cm² (10,450psi) |

| Corrosion Resistance | Tested to ASTM B117 | 5000 hours |

| Flexural Strength | Tested to ASTM D790 | 570kg/cm² (8100psi) |

| Hardness | Rockwell R to ASTM ASTM D785 | 85 |

| Heat Distortion | Tested to ASTM D648 at 264psi fibre stress. | 20°C Cure 46°C 100°C Cure 82°C |

| Heat Resistance | Suitable for use in immersed conditions at temperatures up to: Resistant to dry heat up to: | 70°C 200°C Dependant on load |

| Chemical Resistance | The product resists attack by a wide variety of inorganic acids, alkalis, salts and organic media. |