Pumps & Valves

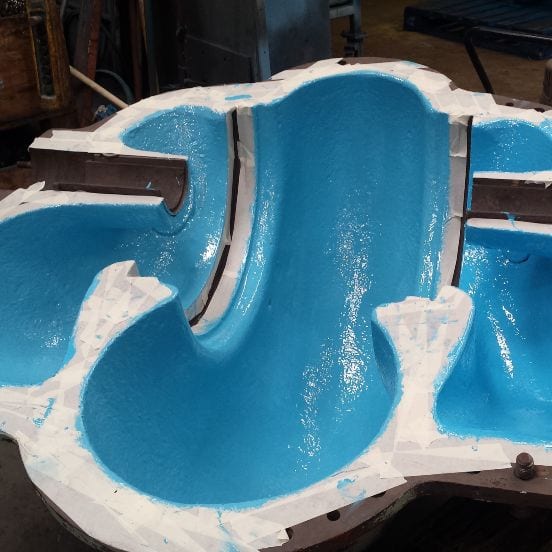

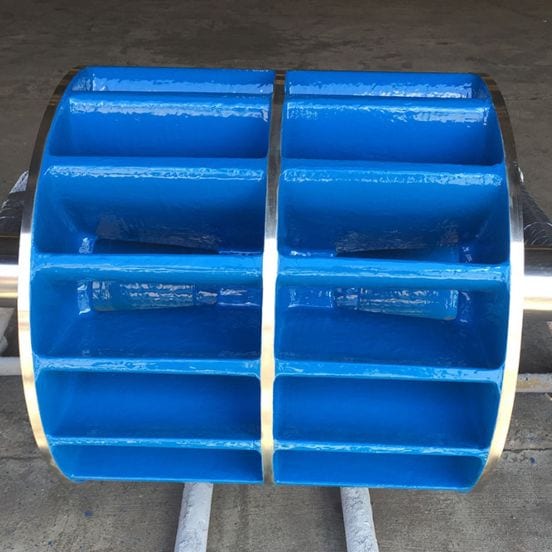

Epoxy ceramic coatings are often used to protect pumps and valves from corrosion and wear. These coatings consist of a two-part epoxy resin and a ceramic filler that provides hardness and abrasion resistance.

When applied properly, epoxy ceramic coatings can provide excellent protection against chemical attack, erosion, and corrosion. The coating can also help to reduce friction, improving the flow of fluids through the pump or valve.

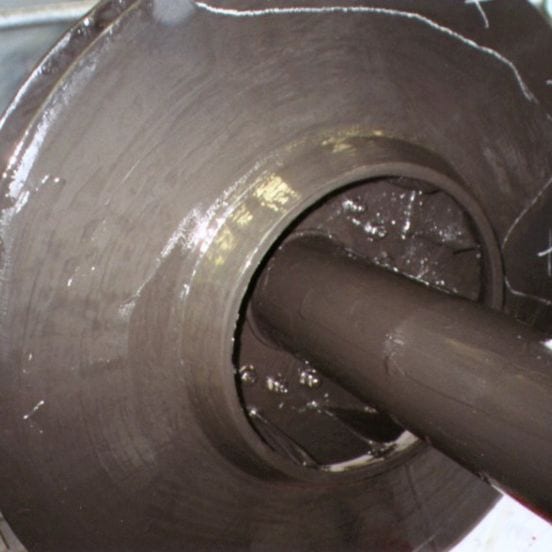

To use an epoxy ceramic coating to line pumps and valves, the surface must be properly prepared by removing any rust, dirt, or other contaminants. The surface should then be roughened using a blasting or grinding process to ensure good adhesion of the coating.

The epoxy ceramic coating is then applied in multiple layers, each layer being allowed to dry before the next is applied. The number of layers required will depend on the application and the thickness of the coating required.

It is important to follow the manufacturer’s instructions for mixing and applying the epoxy ceramic coating, as well as the recommended curing time. After the coating has cured, it should be inspected for any defects or imperfections, and any necessary touch-ups should be made.

Overall, using an epoxy ceramic coating to line pumps and valves can help to extend the life of these components and improve their performance.

Recomended Ceramic products for Pumps & Valves

-

M-CERAMIC 100 – Epoxy Ceramic Putty

£97.30 – £247.00 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page -

M-CERAMIC 200 – Epoxy Ceramic Coating

£100.80 – £255.80 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page -

M-CERAMIC 300 – Epoxy Ceramic Efficiency Coating

£104.40 – £266.25 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page -

M-CERAMIC 500 – Epoxy Ceramic High Temperature Coating

£120.60 – £303.40 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page -

M-CERAMIC 700 – Polyurethane Impact Resistant Coating

£129.50 Excl VAT Select options This product has multiple variants. The options may be chosen on the product page